The highest quality molds, created from advanced technology

and sophisticated craftsmanship.

Molds

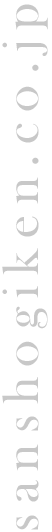

Plastic molding dies

- We manufacture over 400 ultra-precision molds a year crafted to a 0.001mm level of accuracy.

- Sansho Giken’s molds are are easy to maintain, and can perform stable molding over many years.

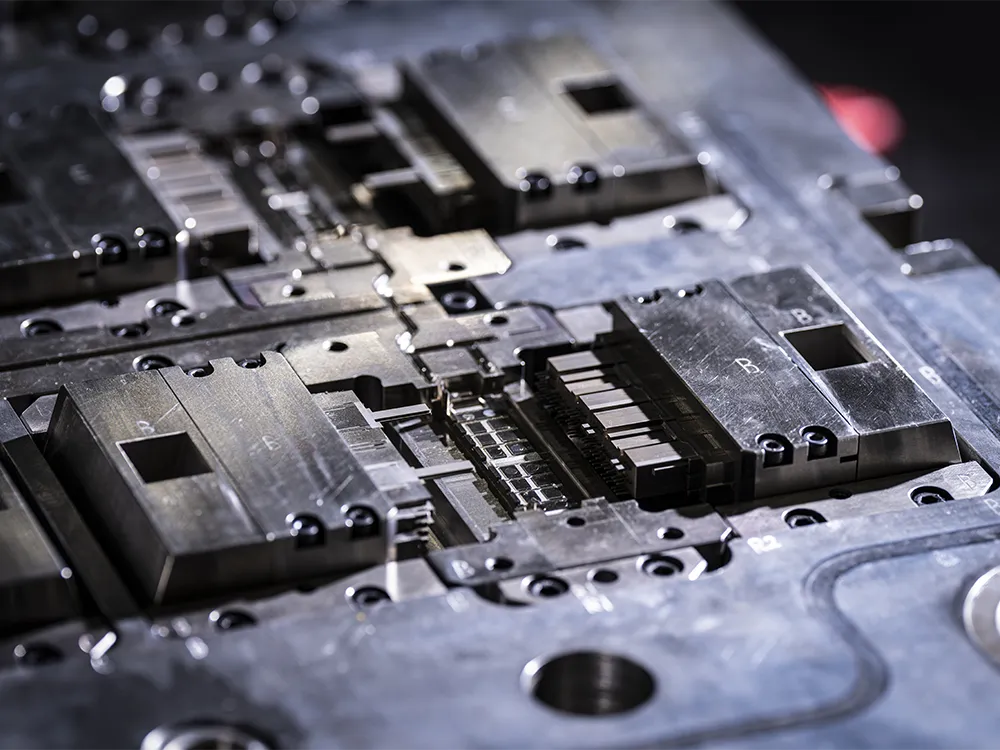

Die-casting molds

- We can also manufacture zinc, aluminum, and high-strength, lightweight magnesium casting molds.

- We handle everything from mold manufacturing to casting and finishing.

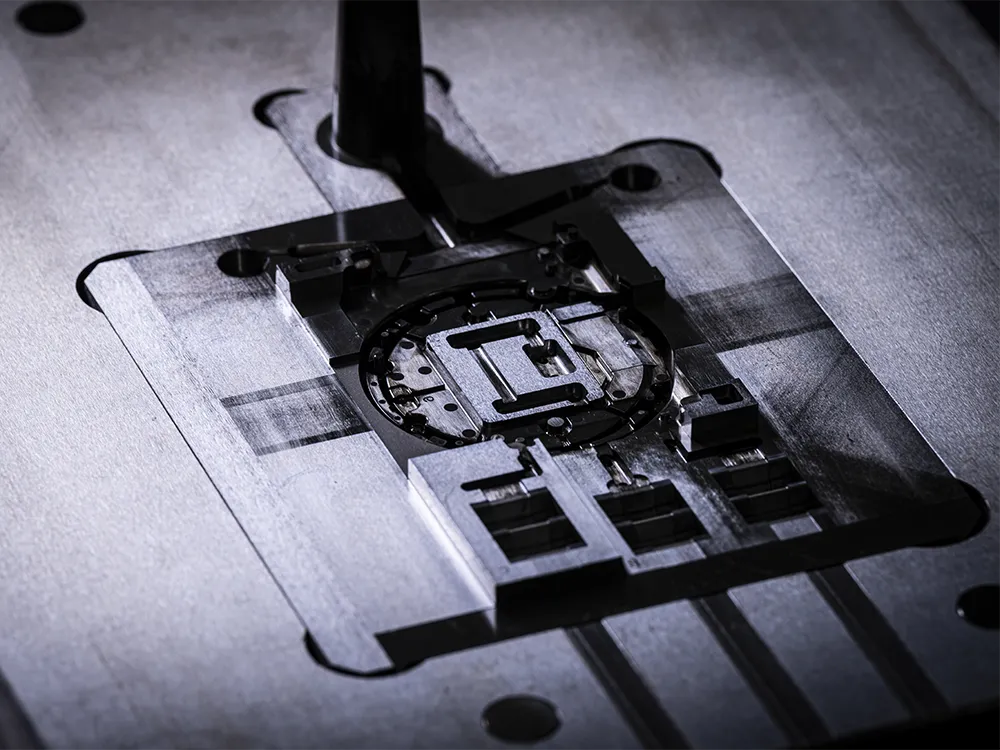

Press molds

- We also design and manufacture progressive press molds.

- We handle everything from terminal bending and plating to subsequent assembly.

Design of precision molds

DR meetings (design review meetings)

- In order to create better molds, the design, assembly, processing, and trial molding departments hold meetings to conduct design reviews.

- We eliminate all conceivable defects before starting, which allows us to more quickly pass quality tests and deliver.

Flow analysis

- We perform flow analysis using 3D TIMON to calculate optimal gate positions and predict the orientation and amount of deformation of resin.

- This allows us to manufacture molds taking into account the predicted amount of deformation.

Cycle time reduction

- Through proper arrangement of water-cooling pipes, molded components can be cooled quickly for shorter cycle times.

- We can also handle the installation of complex water pipes using metal 3D printers and diffusion bonding technology.

Precision mold manufacturing

Manufacture molded components using various processing equipment

he processing team in the Precision Machinery Department transforms the designs from the Engineering Department into actual molds. We are able to manufacture molded components with such high precision because we have highly refined processing techniques that cannot be achieved by machines alone. And we are passing these processing techniques down to a new generation day by day.

Mold assembly

The assembly of precision molds requires a high level of craftsmanship, including fine hand finishing. This is a very important final process that crystalizes the entire process from design to processing into a single mold. High-quality precision molds finished with painstaking assembly can provide stable production.

Quality Control

Reliable quality from a reliable inspection system

A highly accurate mold inspection system is an essential part of manufacturing reliable precision molds. Various high-precision inspection equipment and dedicated inspection staff play important roles in ensuring reliable quality.