Materializing ideas and

responding to ever-diversifying needs.

- We have realized almost 100% in-house production with our connector components.

- The manufacturing of connectors, which have complex shapes and require advanced manufacturing techniques, has been reduced to one linear sequence of processes, from the molding process to the metal terminal insertion, visual inspection, function inspection, and tray-packaging processes, thereby reducing costs while achieving high quality.

- Production of custom-made automated machines to fit customer needs.

- We mainly manufacture automated machines to manufacture connectors used in automobiles, but we also design such machines for manufacturing and mass-producing home appliances and medical equipment components.

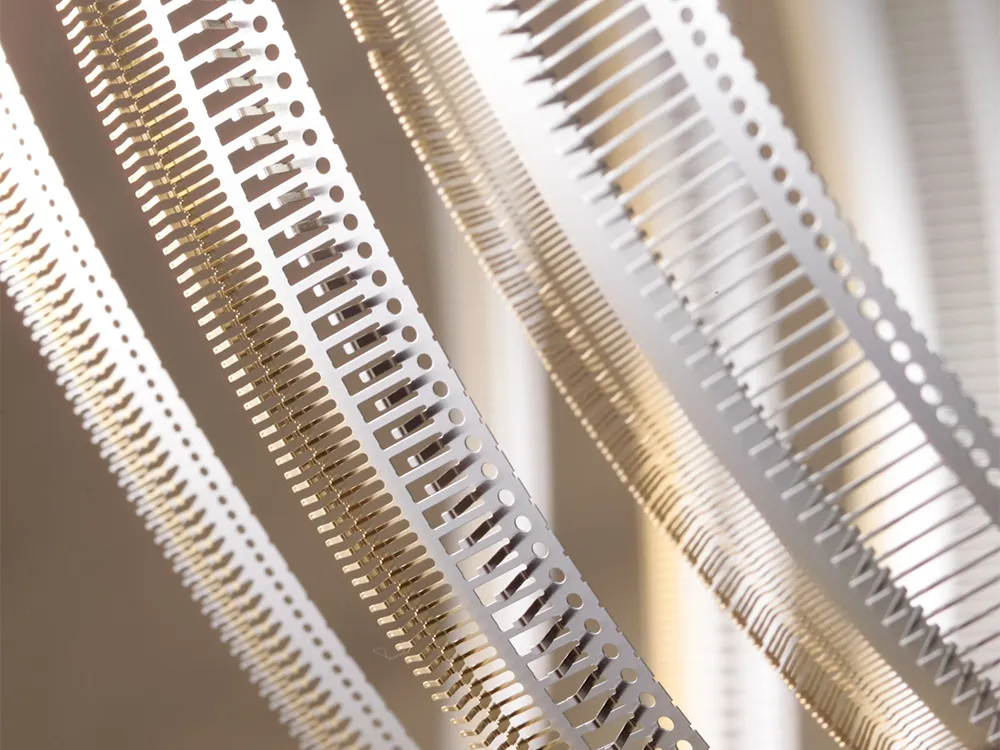

- We have press machines ranging from 10 tons to 80 tons, and are also equipped with supplementary equipment such as automated winding machines.

- We manufacture products such as small pitch terminals for BtoB use, terminals for automobiles, and press-fit terminals while realizing lower costs through unmanned operation.